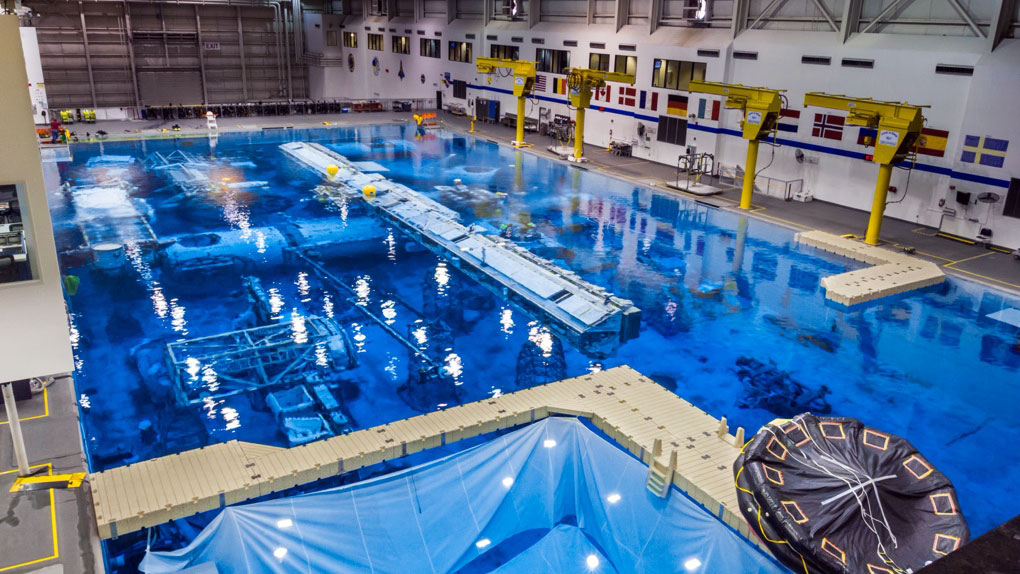

Though the day dawns cool, the deck of NASA's Neutral Buoyancy Laboratory (NBL) remains warm—a side effect of keeping 6.2 million gallons of water at a constant 86°F. I stare down into the largest indoor body of water in the world and feel a surge of vertigo. Here, astronauts practice for spacewalk missions at the International Space Station (ISS), and today I'll watch them do it.

The pool measures 202 feet long, 101 feet wide, and 40 feet deep, extending 20 feet down from the elevated deck and then an additional 20 feet below the floor level. Its wall and floor are white, though they're smudged and darkened from years of repositioning model test stands. Spread throughout the water are life-sized component mock-ups of the ISS, looking exactly like some giant child's Tinker Toy set. Refraction causes the perspective to bend sharply away until it's obscured by the reflection of the ceilings and walls.

"Man, that is a deep looking pool," I say, leaning over to stare at the bottom of the clear water. My brain tries and fails to conjure up eloquence. It's busy, filled with thoughts of tumbling over the side.

The pool loses about 5,000 gallons per week in evaporation, and I can feel the moisture in the air. It's nothing like the awful humid summers we typically have in Houston, where the NBL is located, but the transition into the pool area does feel like passing through an insubstantial curtain. The air in the high bay smells faintly of chlorine, and it hums with pumps and machine noises. Scratchy PA announcements occasionally echo down from speakers in the distant ceiling.

"What's it like being underwater?" I ask my companion, safety diver Chris Peterman. The NBL has 28 full-time divers, all of whom work for Oceaneering, a company specializing in underwater engineering efforts.

"It's incredible diving," replies Peterman. "It takes a long time to sink in how large it is and how much stuff is in there."

Even the largest pool in the world isn't anywhere near large enough to hold the entire space station, though. The most recognizable feature of the space station is its backbone Integrated Truss Structure, which stretches longitudinally and holds the station's radiators and solar arrays. Eleven individual segments make up the truss; the NBL pool can hold only three of them end-to-end. The ISS is really, really big.

Whether you regard it as humankind's greatest laboratory or the costliest white elephant ever sold, the International Space Station remains an engineering marvel. Bolted together by men and women over more than a decade while skipping along at 17,500 miles per hour 200 miles up, the ISS is longer and wider than a football field, with a mass of almost 450 tons (though its precise mass varies depending on the amount of consumables currently on board). Its assembly required 37 space shuttle launches, and that's not counting the additional components launched by Russia, or the Soyuz launches to keep the station crewed, or the Progress launches to keep it supplied.

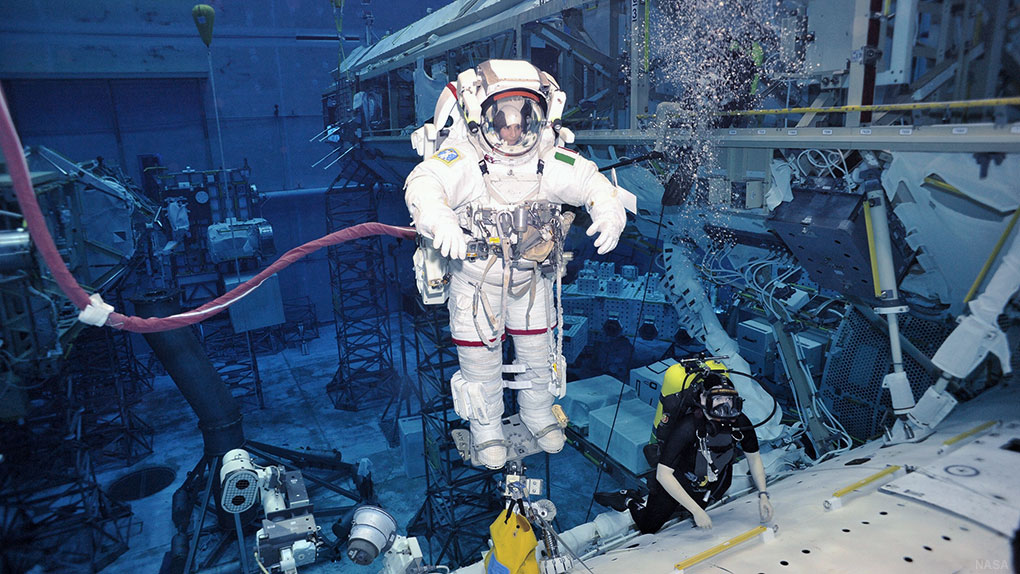

A total of 155 spacewalks over ten years were needed to connect the components together—2.5 times as many spacewalks as had previously occurred in the entire history of manned space flight. Every second of every one of those of those spacewalks had to be planned and then rehearsed dozens of times. Unfortunately for the astronauts and engineers, assembling things in microgravity differs from assembling them on Earth—in addition to the obvious problem of your tools floating away, the human mind isn't used to accounting for an object's weight and mass as separate properties. Spacewalk rehearsals therefore have to happen in as close an environment to microgravity as possible.

How on earth do you simulate microgravity? Two ways. First, you can recreate it by flying parabolas in a plane. This works, but only for thirty seconds at a time. NASA does this with a Reduced Gravity Aircraft (popularly known as the "Vomit Comet"). It's useful for microgravity acclimation and limited testing but not for rehearsing multi-hour spacewalks. So the second rehearsal strategy comes into play: build the largest pool in the world and go swimming—exactly what NASA did.

Refraction plays games with perspective when looking across the pool.

The size of the International Space Station compared to an American football field.

Water is relatively dense stuff, so you can simulate microgravity in a pool by putting an astronaut into a suit and adjusting that suit's weight until it neither floats nor sinks—making it neutrally buoyant. That, essentially, is why the NBL was built. It's a simple premise that requires complex execution. To properly train for microgravity, everything needs to be neutrally buoyant—the astronauts, their tools, and anything they will manipulate while underwater. You need people and facilities to build all these floating tools and mock-ups. Plus, you need a pool big enough to hold a mock-up of the thing you're training to spacewalk around.

The astronauts, stars of today's show, now enter the facility. Luca Parmitano of the European Space Agency and Chris Cassidy of NASA's astronaut corps wear white tube-filled liquid cooling garments and blue paper surgical booties. Everyone heads for one of the test coordinator control rooms for the pre-dive briefing; I find an unobtrusive spot from which to take pictures and end up near a small spread of coffee and Einstein Bros. bagels. Parmitano's shaved head and slight goatee make him appear somewhat sinister, but the Italian cracks a smile at the divers and then makes directly for the bagels. Cassidy is utterly laid back, looking almost sleepy—which he might be, because it's a hair before 0800 and he's likely been up for hours already getting prepped for the dive.

The NBL folks all do a valiant job of not noticing me; everyone focuses on the small projector screen in the back of the room. Parmitano munches his bagel through the briefing. It's the last food he'll get for six hours—once the astronauts are in the pool, they stay in the pool until the test is complete.

The mission briefing

The briefing is short since the room is full of practiced professionals who have done this many times before. One of the test coordinators (TCs) outlines the dive, and astronauts Cassidy and Parmitano listen intently. They will shortly be underwater, moving on and around the enormous mock-up of the International Space Station, to practice routing a power cable needed to make a future connection to the Russian Nauka module (currently set to launch in 2014). After that, they will practice performing maintenance on one of the delicate and complicated rotary joints that attach the solar arrays to the Integrated Truss Structure and allow the long panels to move about. The TC talks through the planned dive, describing objects and tasks in terms of their location and orientation to the ISS's orbital plane—port, starboard, nadir, zenith.

Luca Parmitano and Chris Cassidy, following along with the dive briefing.

After the PowerPoint presentation ends—yes, NASA uses PowerPoint, just like any other office—attention turns to the front of the room. The dive team lead reminds the divers about lighting conditions and requests that the safety divers give the camera divers adequate room to document the astronauts' activities. The dive will have numerous "translations"—the astronauts will move quite a bit from place to place on the mock-ups—so the camera divers are instructed to plan their routes accordingly. The lead reminds the divers to take a spare air tank with each of them. The test director then performs that most iconic of NASA activities: the go/no-go callout.

”Flight lead.“

”Go.“

”TC.“

”Go.“

”EV1.“

”Go.“

”EV2.“

”Go.“

”TSO.“

”Go.“

”Dive suit.“

”Go...“

The final station call is set at 8:20am and the room begins to disperse. Parmitano and Cassidy—referred to as "EV1" and "EV2" in the callout—quietly talk with some of the NBL workers. I slip back downstairs, walking across the pool deck to the other side, next to the four yellow pneumatic jib cranes that will lower the suited astronauts into the pool.

The gear

The upper half of Astronaut Luca Parmitano's extravehicular mobility unit, mounted on the donning stand.

Toothpaste is perfect for keeping dive masks fog-free.

The suits are laid out here and ready for donning, with the upper halves affixed to large metal frames and the lower halves lying on white pads on the deck. Tool and suit lab engineers walk up and down, preparing tools for use. Among them is EVA (extravehicular activity) Suit/Tool Engineer Bert Knight, who has been working for the space program for almost a quarter-century (as attested by a picture on his desk showing him in some truly unfortunate early 1990s pants).

Parmitano and Cassidy descend to the deck beside me and begin donning their suits. My perception of how long it takes to get into and out of a spacesuit has been clouded by a lifetime spent watching science fiction movies. Here, on the deck of the NBL, it takes Knight and another suit engineer fifteen minutes to help Cassidy pull on the pants, shrug into the top half of the suit, connect the liquid cooling and ventilation garment and all the other hookups to the long umbilical cable, and then don and seal the helmet. After this, Knight begins hanging tools and equipment on the rack—called the "mini-workstation"—on the front of Cassidy's suit. The astronaut endures the poking and prodding stoically, though I wonder what happens if his nose starts to itch.

Cassidy is soon ready to go, but Parmitano, on the other side of the rack and facing away from me, has an issue with his suit's communication systems. There's a pause and the technicians swap parts out; to my left, the divers lazily tread water out in the pool with the mock-up sprawled out far beneath them. Most are busily applying toothpaste to their dive masks to prevent them from fogging up. We wait.

Time passes...

The tour

The facility that today houses the Neutral Buoyancy Laboratory didn't start out as a pool or even a laboratory. The building was originally constructed by McDonnell-Douglass in the early 1990s to build and process on-orbit parts for Space Station Freedom, a much larger forerunner of the ISS which was cancelled before any hardware was launched. The building that would become the NBL was constructed with a perfectly smooth floor so that huge space station components could be effortlessly floated around on air bearings—sort of like a reverse air hockey table. It was located a stone's throw from Ellington Field so that components could be floated out the rear of the building and loaded directly onto transport aircraft to be shipped away for launch into space. Plans change, though. Space Station Freedom fell victim to spiraling costs and too many shifting design goals, and the construction and assembly contracts for Freedom were canceled or altered to focus on Freedom's successor, the International Space Station. McDonnell-Douglass found itself with a huge building and nothing to do with it.

At the same time, NASA was conducting a study on building a new neutral buoyancy simulation pool. The existing pool was in a facility named the WETF, the Weightless Environment Training Facility, located on-site at Johnson Space Center (JSC) in building 29. It was big—big enough to hold a mock-up of the Space Shuttle cargo bay—but nowhere near big enough to practice ISS assembly. NASA had originally planned to build a new weightless training pool on-site at JSC and had allocated funds to pay for it, but the plan was canceled in late 1990 after Congress ordered Space Station Freedom to be redesigned to be smaller and less-expensive. Rather than build a new weightless training facility from the ground up, NASA went shopping for existing buildings that might fill the need, and McDonnell suggested the empty station assembly building. Starting in 1995, the carefully engineered floor was torn up and replaced with a pool of truly epic proportions. The work was completed in 1997, and the buildings housing the NBL and its attached offices were renamed the Sonny Carter Training Facility after deceased astronaut Manley Lanier "Sonny" Carter, Jr.

Running a facility on the scale of the NBL requires more than just a huge hole in the ground to put all the water. Before watching Parmitano and Cassidy dip into the pool for their training run, I'd been taken through the facility by safety diver Chris Peterman. We started in the south work bay, with the southern wall of the massive NBL tank rising 20 feet up in front of us. The east wall holds dozens of signed photographs and mementos—sweatshirts, T-shirts, and signed flags, many of which had been flown in space and worn by astronauts. The relationship between the astronauts and the NBL staff members who support them is a close one; the bond is obvious when looking at the signed row of gifts.

Nestled underneath the south overhang of the pool wall are both a hypobaric and a hyperbaric chamber. The hypobaric chamber is used by NASA to simulate the effects of altitude sickness and loss of pressure, which can bring on nausea, giddiness, loss of coordination, and other scary effects. The hyperbaric chamber serves as an emergency decompression chamber for the divers. Peterman and I headed north up the west side passageway along the long edge of the pool, two floors beneath the working pool deck. Pipes and tanks fill the corridor. All the cranes except the two huge overhead models in the high bay are pneumatic; they're critical to getting astronauts in and out of the water. Redundant compression systems provide backups should the main units fail, but as a last resort Peterman informed me the divers can actually use their breathing gas supply to power the cranes long enough to pull astronauts out of the water in an emergency.

Looking down one of the north-south corridors running along the bottom of the NBL pool.

By far the largest pipes are the enormous supply and return lines for the pool itself. "We can turn the pool over"—that is, replace every drop of water inside of it—"every nineteen hours," said Peterman. "Right now, we're turning it over at a little slower pace, for energy conservation."

Putting aside its enormous scale, the water treatment system used for the NBL pool is the exact same type as you'd find in a home swimming pool. The system is computer controlled, and it automatically monitors the water's temperature, pH, and chlorination levels. It keeps those parameters all within the desired bounds. Outside the north end of the building sits the huge water treatment plant itself. Next to that are the four enormous sand filters, connected to a series of pipes and valves which disappear into the concrete foundation. It's not that different from the pool equipment in my neighbor's back yard—there's just much, much more of it.

The enormous sand filters which keep the NBL pool clean. These are just like the ones you'd use at home—only much bigger.

The suits

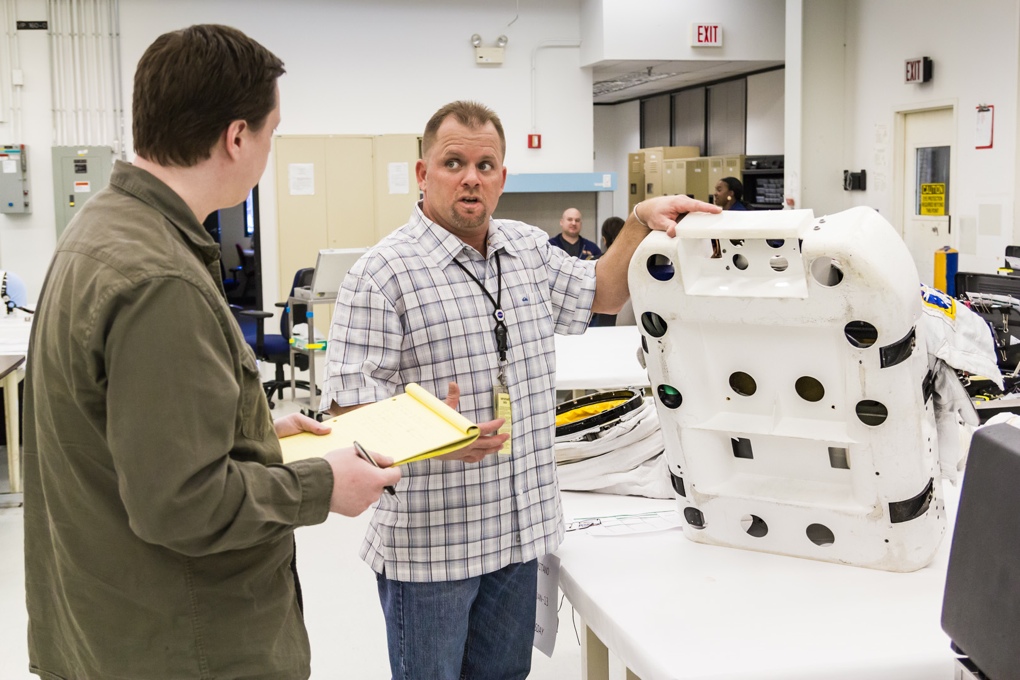

Back inside, we enter Bert Knight's domain, the Suit and Tool Lab. Sitting in one corner of the NBL, the lab can make or break an astronaut's career.

Each astronaut candidate gets measured here not just for an underwater-spec training suit but also for an actual flight suit. The fitting process involves taking 37 different anthropometric measurements of the candidate's body and another 40 of the candidate's hands (20 per hand). These are designed to break the body down into a series of statistics, which are then analyzed by a computer program that produces a predictive sizing sheet. The sizing sheet is used to pick off-the-shelf suit components, which are then extensively adjusted to fit each individual.

Gloves are the most carefully sized components, with astronaut candidates working their way through more than a half-dozen "glove pick" pairs before finding a close enough fit to proceed. (Even "identical" gloves manufactured to identical specs will vary to tiny degrees; the amount of innervation in the human hand means that minute variations in the spacing of the seams—even variations within the tight tolerances required by NASA—can be felt. Arriving at completed gloves that are comfortable for each astronaut is a long process.)

The NBL's Suit and Tool Lab, where "spacesuit tailors" work to fit and customize suits for astronauts.

The lab fitting can actually disqualify astronaut candidates from the space program. The suit fit-check involves donning the entire thing and performing a series of motion and movement tests—being unable to reach all of the controls on the chest-mounted display and control module has been a reason for disqualification in the past.

"You're going from 14.7 PSI and you're jumping into a suit that's pressurized to 4.3 PSI, so we're bumping you up one atmosphere and you're fighting all this pressure," Knight told me. "I can't just go out on the street and grab a guy and throw him into the suit and say 'go do this.'"

An EMU demonstrator stands on one wall. Burt Knight used this to give us a good feel for a spacesuit's controls.

"One of our biggest concerns and one of our biggest requests of anyone getting in the suit is: don't fight the suit," he said. "You're gonna lose every time. It'll wear you out. You've got to understand the capabilities of the suit, the functions of the bearings, how certain things move... and if you're claustrophobic, forget it." He shook his head. "It'll be like sticking you in a coffin and saying, 'Hey, we'll be back in six hours!'"

Knight led me to a table laid out with a smorgasbord of additional hardware to explain what he does in more detail. "Not only do we supply the suit" he said, "but we also supply what we call ancillary hardware—socks, underwear, t-shirts."

Luca Parmitano's extravehicular mobility unit (EMU) suit being prepped for the dive.

"Are some of those off the shelf?" I asked. "Or do you make them?"

"Nothing we supply is off the shelf. You could not go to an Academy or Sports Authority or anywhere else and buy what we use. Now, we could go to Academy or Sports Authority and buy something similar to what we use and use it, but we don't. We keep it all in house. We have different contractors that we buy from. Like with the diaper."

I had... noticed the diaper. Knight picked it up.

This is not a space diaper. This is a "maximum absorbency garment."

NBL suit engineer Don Smith, working on Luca Parmitano's EMU

"We could go to Walmart—or actually, we could go to Bubba's house," Knight said, pointing to an engineer named Don Smith, who didn't look up from the adjustments he was making to Luca Parmitano's dive suit, "go under his sink, and find a ton of these, and we could possibly fly them, but we don't."

Smith looked up and held Knight's gaze for a second before replying. "I don't use those. I use Depends, thank you very much."

I couldn't help but laugh—the office humor was so absurdly normal in this exotic spacesuit-filled lab. "I'm sorry, Bubba," Knight chortled, as Smith shook his head and returned to his adjustments. "Anyway, you guys know this is a diaper, but we don't call it a diaper. This is a MAG—a maximum absorbency garment."

"They put on one of these in the pool, too?" I asked.

"Every time," nodded Knight, successfully knocking a bit of the glamor off my dashing image of astronauts. "I'm glad you said that, because there's two things you gotta remember: one, they have to wear this on orbit. You're gonna be in a suit eight to ten hours....Now here in the pool, it's six hours max." He held up the MAG for my photographer to get a good shot. "But two is...we want them to get used to wearing this thing. So they have to put this on, then they put their TCUs on, their thermal undergarments, then they put this garment on"—here he held up a large white full-length mesh garment with tubes running all throughout it—"which is the LCVG, and this is the last thing they put on before they climb into the suit."

The LCVG, or liquid cooling and ventilation garment, performs the vital function of regulating an astronaut's temperature. Cooling water is circulated across the astronaut's body through a network of tubes, absorbing and carrying away heat. In orbit, the water runs run through the astronaut's backpack where its heat is removed; in the NBL, the water is supplied by the pool-side support equipment through the umbilical. The LCVG also functions as the air return for the suit, drawing in atmosphere from near the astronaut's extremities, circulating the breathing gas around within the suit and equalizing pressure in the suit.

LCVGs in one form or another have been in use since the dawn of spaceflight, but the concept of a self-contained water recirculating and cooling loop can be traced directly to the Apollo program, which was the first time astronauts left a spacecraft without some form of tether. The LCVG is a critical component of the suit's life support system.

Knight then showed me a demo suit hanging up on a rack and pointed out the chest-mounted display and control module (DCM). The DCM is big, bigger than the plastic lunchboxes we used to carry to grade school, studded with oversized controls designed to be manipulated by gloved astronaut fingers. The DCM, Knight explained, is like the dashboard of a car. It has some gauges and some controls, and any astronaut needs to know what they all do. A number of the control labels on the front of the DCM are written backward; this is because they can't be seen directly by the astronaut, but instead are designed to be operated with one hand while observing them via a wrist-mounted mirror on the other arm.

Hanging on the back of the suit is the PLSS backpack—the Primary Life Support System, pronounced "pliss." Where the DCM is the suit's dashboard, the PLSS is the engine, supplying oxygen, battery power, and cooling water to the suit.

Close-up of a spacesuit's display and control module (DCM). Note the backward labeling, intended to be read with the aid of wrist-mounted mirrors.

Attached to the front of the suit, whether it's in the pool or on-orbit, is the complicated metal harness called the mini-workstation. The mini-workstation is designed with slots, branches, and clip-holes into which a huge variety of different tools can be fitted. By far the neatest thing we were allowed to see was the body restraint tether (BRT), which is a large flexible tube-like tool used to fix an astronaut's position relative to an object. One end of the BRT mounts solidly to the astronaut's suit, and the other end is affixed to a station rail or other attachment point. The long middle section is made up of a number of socketed ball joints and is totally flexible until one end is twisted; the twisting applies tension to an internal wire, and the ball joints lock up against each other, freezing the BRT into a solid shape.

Much of this gear is absent on the suits used in the NBL. The PLSS backpack is replaced with a weighted plastic shell, since the NBL facility pipes in the astronaut's water and air and power through a long set of cables. The suit's helmet, with its layered sets of polarized sun visors and opaque shades, is replaced with a much simpler shell helmet which still holds pressure but lacks any fancy shielding. And the DCM, with its unneeded electronics, is replaced with a featureless, weighted blanking plate.

Roll over the circles to learn about the tools on the suit.

NB-PGT (Neutrally Buoyant Pistol Grip Tool)

Neutrally buoyant analog for the pistol grip tool (PGT), a fancy cordless drill. Used for extraction and installation of bolts, and also used to torque bolts. Would be replaced with a real PGT if this were a real EVA.EMU Wrist Mirror

Extravehicular mobility unit wrist mirror. Used to let the astronaut see things on his suit below his chest, since he can't bend his head forward and look.RET (Retractable Equipment Tether) — x2, one on PGT, one on bag

Anytime small items are to be transferred between crewman and crewman, or between crewman and bag, or between crewman and a structure, a RET must be used to ensure the item doesn't float away. In this case, astronaut Cassidy has 5 RETs, so he’s going to be doing lots of equipment transfers.Mini-Workstation Swing-Arm

Swings to stow itself up against the astronaut's side, and provides additional bayonet receivers and clips for tools.6-foot Waist Tether

Used to anchor crewman at various sites on the structure, just to hold position. This is called "local tethering," as opposed to more permanent attachment with the big 85-foot safety tether.Bayonet Receivers

Fittings for attaching tools to the mini-workstation. Tools and things like the EVA trash bag have bayonet fittings that are mated to these receivers.RET (Retractable Equipment Tether) — unattached

Spare RETs. Astronaut Cassidy's loadout here includes 5 total RETs.85-foot Safety Tether

When a crewman comes out of the airlock, this safety tether is immediately hooked to a designated position just outside the airlock. That way, the astronaut is always connected to the station no matter what.End Effector — AKA “Grabber Daddy”

Another tethering device, used to quickly grab onto a structure and temporarily anchor an astronaut there. Not used as much as the waist tether or the BRT.EVA Trash Bag

Small pouch with a double-flap opening. Gives the astronaut a place to stow bolts or other miscellaneous small items during the EVA so they don't float away.RET (Retractable Equipment Tether) — unattached

Spare RETs. Astronaut Cassidy's loadout here includes 5 total RETs.D-Rings with D-Ring Extensions

The D-rings are used as attachment points for various things with clips, but the astronaut can't see them. So they have "extenders," the tethers coming down from them, which the astronaut can flip up and see.D-Rings with D-Ring Extensions — astronaut's right D-Ring is attached to 6-foot waist tether

The D-rings are used as attachment points for various things with clips, but the astronaut can't see them. So, they have "extenders," the tethers coming down from them, which the astronaut can flip up and see. This extender is the end-point of Cassidy's 6-foot waist tether.BRT (Body Restraint Tether) clip

Secondary attachment point for the body restraint tether (BRT).BRT (Body Restraint Tether) — stowed position

Flexible tool used to fix and hold an astronaut in position relative to a structure when he or she is going to be performing a task. The BRT consists of an interlocking stack of spheres and can be rigidized to lock the astronaut into a specific position and orientation. It is also used to carry cargo—tool bags, crew lock bags, or bigger bags are clamped in the jaws and dragged behind the astronaut. The two cylindrical brass-colored knobs are used to adjust the BRT's joints once it's rigidized. The vertical knob rotates the elbow, and the horizontal knob rotates the wrist.RET (Retractable Equipment Tether) — unattached

Spare RETs. Astronaut Cassidy's loadout here includes 5 total RETs.

Weighting the suit to neutral buoyancy becomes a question of managing the suit's air volume. A small astronaut might have a relatively large volume of air inside his or her suit and might require extra weights; a larger astronaut will have much less air volume and might actually require some foam to add back buoyancy.

As for the rest of the astronauts' tools, we were restricted from taking photographs of some because they are export-controlled technology—close-up details of some of the specialized tooling can't be shown to non-US citizens. In general, though, the tool lab manufactures multiple sets of tools for use specifically in the NBL. Where applicable, they produce both the functional version of the tools and the plastic neutrally buoyant versions.

Bert Knight hefts the plastic mock-up of the PLSS backpack used underwater.

The safety divers

I spent half of my nine years at Boeing working in the building immediately adjacent to the NBL—the 91-14 building, or "Tower 2" as we called it—and the safety divers of the NBL were the subjects of many whispered tales. Rumor had it that they sat around lifting weights all day and eating catered lunches, occasionally taking a dip in the NBL pool to splash around. Peterman, the safety diver, laughed when I told him the stories on our way back up to the pool deck.

"They like to see us exercise three hours a week," he said. "If there's a break, we do have a weight lifting facility on-site here and we can run down there. We can also swim laps." He nodded toward the enormous twenty-foot-high wall next to us that forms the southern edge of the pool. "It's really trippy, swimming laps over the International Space Station."

The divers' physical condition is closely monitored, since they're tasked with the safety of the astronauts (or "subjects," as the divers call them).

"Every Monday, we do a physical, and then we renew that physical every day," Peterman said. "If anything changes—if I start taking Benadryl, I have to come in, or ibuprofen, I have to come in for another physical and have them check me out and make sure I'm OK to dive."

"I actually applied for this job ten years ago, right after I became a certified diver," he confided. "But now knowing what I know, I didn't have much of a chance to get the job. When I applied previously I had less than 50 dives and had done little training above the basic 'open water' diver certification. I was comfortable in the water but didn't have enough experience to dive without thinking about what I was doing. A safety diver at the NBL is required to deal with many things coming at them at once, so you must be able to deal with the diving portion of the job on instinct so you can focus on the job at hand, keeping the subjects safe and helping them learn."

The safety divers operate with a standard "nitrox" mixture of 46 percent oxygen and 54 percent nitrogen, and the depth of the NBL coupled with their typical dive time means that decompression rarely poses a problem. Peterman was quick to point out that while the divers almost never need decompression time, there's always the possibility of other problems—such as a gas embolism—that require a hyperbaric chamber to treat. In the NBL's history, no major dive incidents have required use of the chamber to stave off decompression-related problems. Regardless, a full-time medical staff works on-site.

The hyperbaric chamber, next to the pool's south wall. If there's ever a pressure-related emergency, it can be treated right here.

Peterman led me into the SCUBA maintenance area at the northeast end of the NBL facility. High-ceilinged as the rest of the place, it was filled with other dive personnel, seated at desks and looking busy. A large and well-lit clean room dominated the space, occupied by a pair of workers in sterile caps and gowns who worked over a table containing neat lines of small bolts and valves and screws.

This area is used to clean and maintain the SCUBA equipment, Peterman explained. Small amounts of oil or grit can become ignition sources in the nitrox breathing mixture, so all of the SCUBA gear is subject to constant and rigorous inspection to keep it pristine. The gear used by the divers in the NBL is standard commercial gear, but it's put under a pretty heavy usage cycle. Because of this, the divers enforce a strictly controlled maintenance cycle on their equipment. Every piece of gear has a schedule attached to it and its maintenance and usage is carefully recorded. When I asked Chris what he would be doing with his day if he weren't showing me around, he nodded at the tanks and laughed: "Cleaning and maintaining gear!"

SCUBA tank components after being scrubbed free of contaminants inside a cleanroom.

The test coordinator

Planning a simulated spacewalk is hard work. The actual procedures the astronauts step through are generated through a complex set of planning meetings that analyze the requirements of a spacewalk and break it down into smaller and smaller components. Sitting at the top of this pyramid of requirements planning is Zeb Scoville, the EVA task group lead at the NBL.

Scoville manages the test coordinators (TCs). They create the procedures for the spacewalks and shepherd them through the test's development. While the astronauts are in the pool conducting the simulated EVA, the TCs function as the flight controllers, taking the place of Mission Control and operating as if the test were an actual flight.

The astronauts who flew on the shuttle and who are assigned as ISS crew all need some basic familiarity with extravehicular activity—operating outside of their vehicle in a space suit, or "spacewalking." In an emergency, any astronaut could be called upon to don a spacesuit to fix a problem, so everyone gets full training on basic EVA operations.

Zeb Scoville, EVA task group lead at the NBL and test coordinator manager.

Basic EVA familiarization consists of a run of about 20 simulated spacewalks to cover all the basics—the number sometimes varies—followed by another nine runs to actually achieve qualification. After that, the astronauts will get to take occasional dips in the pool to help develop procedures or test new pieces of equipment. The next prolonged bit of underwater work is when they're actually selected for a crew—at that point, they receive at least eight more EVA simulations to brush up on their basic skills and get acquainted with the problems they might encounter during their specific mission. Most ISS missions contain one or more scheduled EVAs, so the astronauts tasked with performing those pre-planned EVAs then undergo three to five additional simulations to learn their EVA's specific procedures.

"For example," Scoville explained as we talked in Test Coordinator Room A, one of the two TC control rooms above the pool, "when they first get into the pool they may grab a handrail and try to pitch their body like this, with their wrist," and he mimicked holding a handrail with one hand in front of him. "Very little moment arm there. So they sort of learn skills where they go like this"— He spread his hands widely apart, one above the other as if grasping two ends of a long handle, and pulled down with the top hand and pushed with the bottom, miming a huge pivot. "And now you have a much bigger moment arm and you get that reaction."

There's even a way to get astronauts comfortable with being swung around on the end of the station's robotic arm. Walking to the window overlooking the pool, Scoville pointed out the controls for the submerged duplicate of the ISS Space Station Remote Manipulator System (SSRMS), which is capable of almost all of the movements and functions its on-orbit SSRMS twin can do. The notable exception is that the underwater version is stationary while the on-orbit SSRMS can "inchworm" itself along the ISS's backbone to reach different areas of the station.

Controls for the NBL's "robot arm"—the underwater Space Station Remote Manipulator System duplicate.

Sometimes the NBL is called upon not to train an upcoming mission but to assist one already in progress. In the event of unexpected happenings on-orbit that require a spacewalk to fix, the NBL is used to work through a full procedure for the spacewalk. An alternate crew acts as stand-ins for the astronauts on orbit. Video from the training runs is sent up to the on-orbit crew, along with a detailed breakdown of the procedure, which the TCs will attempt to construct using the basic task building blocks trained into all of the astronauts.

Scoville pointed out that the ISS couldn't have been built without the NBL. "There is irreplaceable capability you get from neutrally buoyant training in our facility," he said. "You get a true three-dimensional space that you get to work in."

"If you're going to do a surface-based EVA... the NBL may not be the best choice for that," he explained, noting there are other facilities at JSC and other NASA sites that are better equipped to train astronauts for surface EVAs in gravity. However, an asteroid rendezvous mission like the one being talked up repeatedly by the current administration would almost certainly be a good fit.

"An asteroid—at least the asteroids that we have up there and are looking at—would be such a negligible amount of gravity that you essentially have none," he said. "In such a case, there are tremendous advantages to replicating an asteroid in the pool and training on it, even more than training in coral reefs—the biggest being that the NBL has no weather, has crane support, and has attached machine shops to fabricate anything needed for the tests.

Samantha Cristoforetti, an astronaut with the European Space Agency, performing an exercise in the pool with the body restraint tether. (Photo courtesy of NASA)

The Test Director

The array of monitors lining the Test Director control room, allowing the TDs to monitor both the astronauts and the divers underwater.

While Scoville and his TCs are responsible for designing and running the spacewalk portion of a test, there's another group of folks who monitor and manage the NBL facility and infrastructure during a test: the test directors (TDs). They operate in a separate control room and keep tabs on the functional aspects of the simulations, letting the TCs monitor and control the actual tests themselves.

Kurt Otten is the NBL's critical systems manager and one of the facility's TDs. He presides over a stable of systems engineers, each responsible for one of the NBL's critical systems (and, like many of the other folks working around the pool, he's a certified dive master and instructor). These systems include the SSRMS arm fixed to the bottom of the pool, the astronaut life support and cooling water systems, the water treatment system, the video and communication systems in the pool, and several other systems. These engineers work to keep those critical systems operating and available during tests, while the TCs use them to actually conduct the tests.

One notable thing the critical systems engineers control is the plethora of cameras. The NBL pool is fitted extensively with the things: there are 22 pan and tilt cameras throughout the pool in fixed positions, and any number of floating mobile cameras will be operating during a test. The TD control room we met in is dominated by a huge bank of video monitors, so I asked Otten if we could see the camera output for some of them.

He smiled and swept a remote across the wall of monitors; they rippled to life with a happy series of chirps. A few of the monitors were tuned to cable TV channels, but most of the displays showed views of the various pieces of equipment. After staring at the ISS mockups through the surface of the water for a couple of hours, seeing everything from a non-refracted perspective startled me.

"The test director is over the whole test," Otten said. "Everything goes through him or her," he explained. During a test, after the astronauts are fully submerged, the test director passes operational responsibility over to the TCs in the next room. "The TCs are our customers, along with the astronauts....We're making the facility available, we're monitoring all the systems and making sure they're participating and functioning correctly. Any time there's a problem, everything's funneled through the test director."

The TD's control extends to the dive team as well. Each astronaut in the pool has a team of four divers assigned to him or her: two safety divers, one camera diver, and one utility diver. The utility diver is of particular importance, because the utility diver handles the training tools—of which there are two different sets. The astronauts use plastic neutrally buoyant tools to get the "feel" of a motion or operation, but the plastic tools don't actually work. After the astronaut rehearses a particular tool motion, the utility diver will swap out the neutrally buoyant plastic tool with a real, functional tool—it doesn't float like the plastic mock-up, but the astronaut can then perform the operation being tested.

When the actual work has been done, the astronaut will trade the practical tool for the neutrally buoyant plastic mock-up, which they will then re-stow on their suit's mini-workstation (a fancy name for the suit's chest-mounted tool rack).

Kurt Otten stands in front of the test director console, explaining how the NBL runs.

Otten then explained something that hadn't occurred to me—the astronauts themselves breathe the same mix of nitrox as the divers, and their EVA suit's pressure must be carefully regulated in order to counteract the changing water pressure. Pressure in the suit is mechanically regulated to be 4.3 PSI greater than ambient, matching the differential above ambient to which the suits are pressurized in space. However, the pool water imparts an increasing pressure of about 0.5 PSI per foot of depth, so different parts of the astronaut's body are under different amounts of effective pressure. The suit might be at 4.3 PSI at the hips, but the feet are deeper and so might be at about 2 PSI relative to the surrounding water; if the astronaut raises his hands above his head, his gloves might reach almost 6 PSI relative to the water. Astronauts quickly learn to keep their hands below their waists as much as possible in order to keep glove pressure lower so they don't have to squeeze as hard to grip things.

Since the pressure in the suits varies as the astronaut rises and sinks in the water column, the environmental systems vary the flow rate of the gasses to the suit as the pressure changes so that the astronaut can breathe in the appropriate amount of oxygen and exhale the appropriate amount of carbon dioxide. The astronauts aren't wired up with biomonitors before descending into the pool, but the test coordinators do keep tabs on the carbon dioxide output of each astronaut and use those measurements to estimate the astronaut's metabolic rate. From that, the TCs can tell whether an astronaut is working too hard and can re-arrange test activities around the astronaut's level of exertion.

The commercial future

To find out more about these commercial operations, I talked with Angie Prince, the NBL's external customer business development manager. She outlined how the NBL earns extra money when the facility is not needed for astronaut training.

"So before, when we were doing station assembly," she began, "this facility was utilized to its top max capacity, training EVA astronauts on how to assemble the station. Now assembly is done, and we're complete with the station. We still need to train our astronauts, but we don't need to train the same volume of astronauts... and because of that, we have excess capacity."

The NBL's size and depth make the pool an extremely desirable property for other companies. NASA has allowed Raytheon, the NBL prime contractor, to go out and bid for external contracts to use the NBL when NASA doesn't have planned activities. Prince is a NASA employee whose role is to represent NASA to the commercial companies. So far, uptake has been promising. As we walked around the pool, we came across a mockup of a helicopter crew cabin, used by oil companies for emergency egress training; across from that sits a huge inflated life raft. These training classes are the reason for the Nomex clothing being washed and dried below.

One end of the NBL is roped off for use by commercial programs. At right is the blue helicopter cabin mock-up used for emergency egress training.

So far, energy companies have been most interested—the NBL has played host not just to survival training, but also to research and development teams and to teams testing out underwater crane and video systems. British Petroleum in particular has been interested in the NBL, testing out remotely operated vehicles (ROVs), plus validating and iterating on their pipeline inspection and repair procedures.

More than simply utilizing unused NBL capacity, the commercial activities draw in revenue and generate cost savings for NASA. "We still get facility utilization fees, but the large cost savings to NASA and the benefit to outside customers is, I have to have a certain amount of staff to run this facility." As she talked, one of the two large overhead cranes began to rumble on its track, moving with surprising swiftness and dragging its shadow across the pool. "Their salary or their wages are covered by this external activity, so they don't cost me—me as the government—as much money."

Prince pointed specifically to the helicopter mockup, noting that on Monday the NBL divers might support an oil and gas customer doing survival training and then on Tuesday might support a NASA ISS training mission. The goal is to find repeat customers who can help "keep the knives sharp," as Prince termed it, keeping the facility's personnel in the groove.

The dive

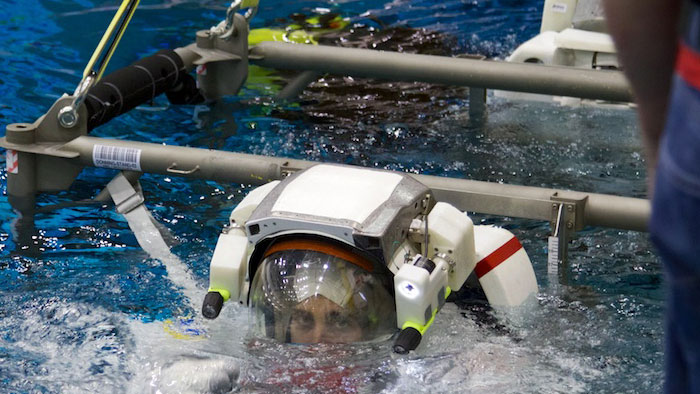

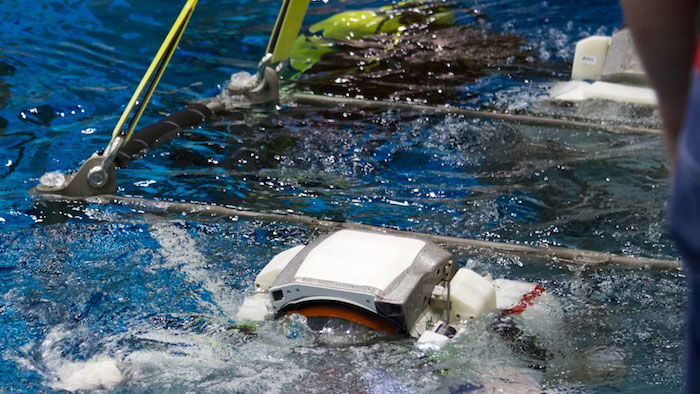

Chris Cassidy is lowered into the NBL pool to start his simulation.

Back on the deck, with Parmitano's comms problem fixed, the dive gets underway again. The staff operates with a calm efficiency. Cassidy gets slowly lowered into the pool's calm surface as his divers hover nearby, ready to unhook him from the platform and move him into position over the truss structure mock-up.

"The one thing I can say about my job and the people I work with is that there's not a lot of people who can do what we do," Knight says, watching Don Smith and others finish their work. Pride is evident in his voice. "This is a very unique job. You can go to another space agency and say, 'Hey, I'm a spacesuit engineer,' and they'll say, 'So? We don't have spacesuits.'"

The feeling at NBL is almost otherworldly. The facility sits within spitting distance of a cluster of Houston neighborhoods, and a bit further away are businesses large and small strung all along the main streets that run throughout Webster and Clear Lake and Friendswood. Yet here, in this large but unassuming building, two spacemen are being lowered by a crane into the world's largest indoor pool to work on a giant mock-up of one of the world's most expensive construction projects.

And beyond the ISS, the commercial future of spaceflight is bright. SpaceX and other companies tackling it haven't yet had much need of the NBL, but as crewed commercial flights become a reality, the facility will play a vital role in preparing people to work in microgravity. NASA's own future plans involve using the NBL for training, but the long lead time until the next set of non-ISS manned missions means that the NBL will need to find more customers to keep its people trained and operating efficiently. One way or another, folks will still dive in the big pool, though after the next few years it's unclear how many of them will regularly be from NASA.

But there are still things to be done in Earth orbit, and the NBL remains the best place to prepare and train the few men and women who ride pillars of fire up into the sky. I focus back on Cassidy and ready my camera to photograph him: astronaut, Naval officer, ten-year Navy SEAL, combat veteran. It's not the 1960s anymore and we recognize that our astronauts are people and not saints, but by any measure this is a brave man who does brave things. Starting in March of 2013, he will spend six months in space on board the ISS as a member ofExpedition 35 and Expedition 36.

I hold down the shutter button, stretching out the moment into a series of snapshots. As the water closes over his helmet, Cassidy tosses me a salute and vanishes.

Design, layout, and coding by Aurich Lawson, Lee Aylward, and Jason Marlin

Photographs by Lee Hutchinson, Steven Michael, and NASA